What Are Dimensions? A Complete Breakdown Of Length, Width, And Height

Home » What Are Dimensions? A Complete Breakdown Of Length, Width, And Height

Table of Contents

Get A Free Quote

Assume you get a product that is damaged due to oversized or tight packaging. Before ordering the packaging boxes, you have to know about the dimensions, such as length, height, and width, which is essential. Here, dimensions play an important role in the packaging to better the unboxing experience.

Additionally, gain insights into the fate of your boxes, shipping costs, space utilization, and product protection that revolves around dimensions. In this blog, users will get knowledge about the dimensions of height, width, and depth.

What is a Dimension?

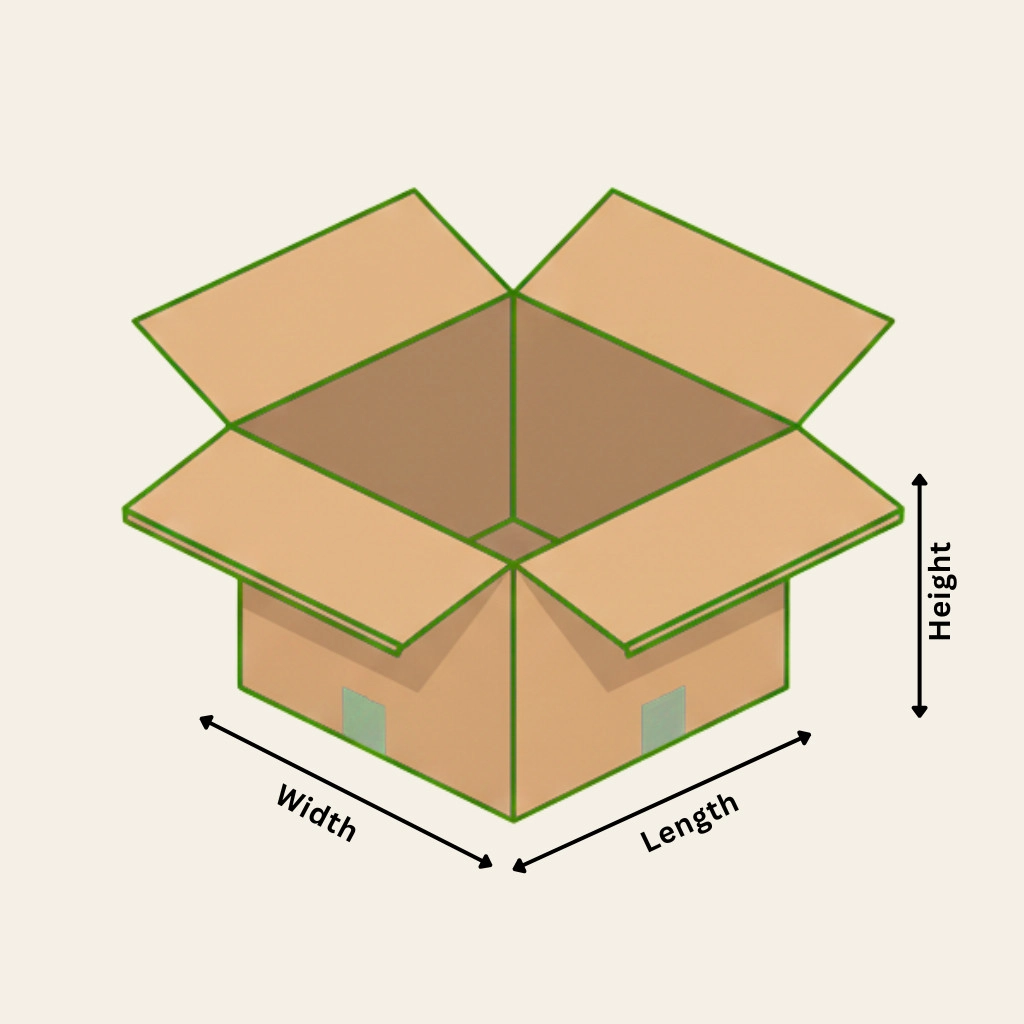

A dimension is a way to measure space. It tells us how big something is or how far it extends in a certain direction. Dimensions usually describe length, width, and height.

In simple words, a dimension helps us understand the size or shape of an object.

Examples:

- A line segment has one dimension: length.

- A rectangle has two dimensions: length and width.

- A box or cube has three dimensions: length, width, and height.

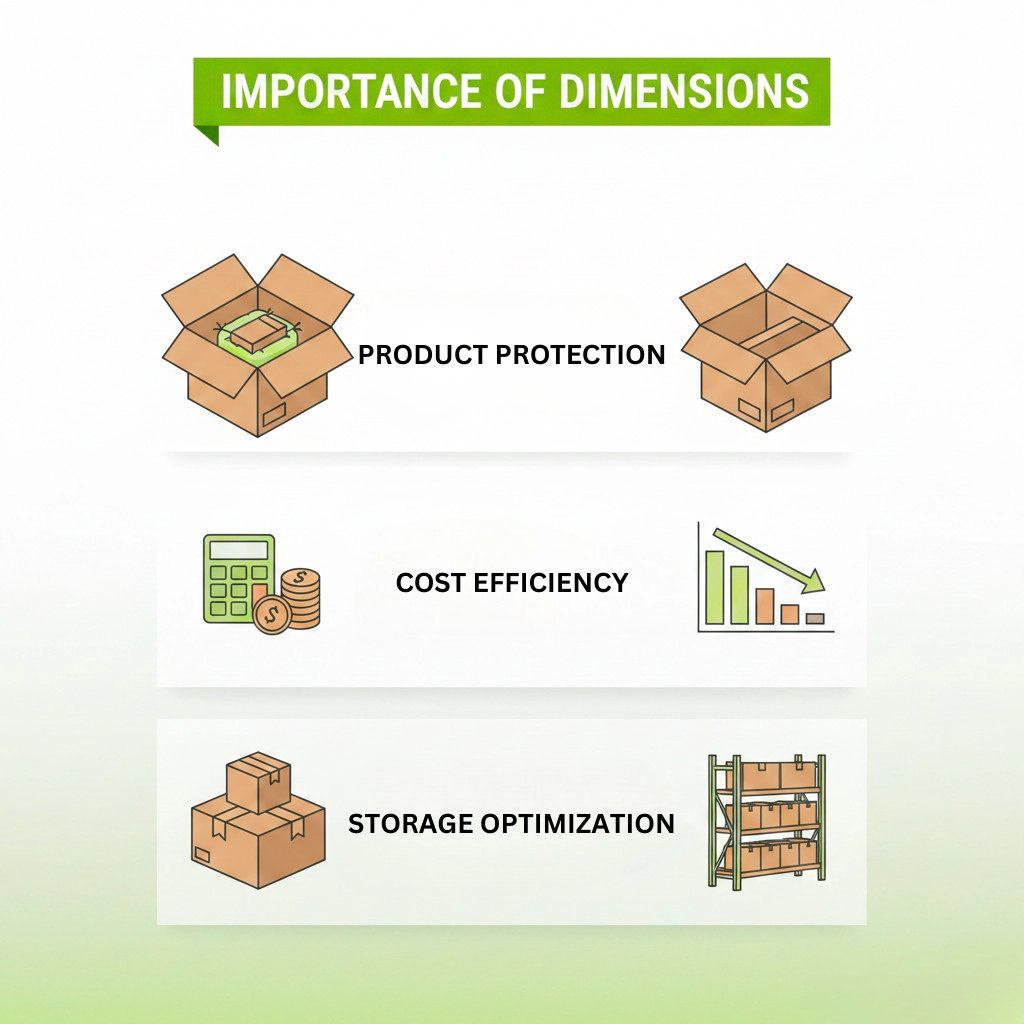

Understanding The Importance Of Dimensions In Packaging

Packaging is the protective case of the product, and minor mistakes can affect the packaging, which can damage the product due to oversized or tight packaging. When it comes to the shape and size, these dimensions play an important role in keeping the accurate size and shape to protect the object. The following are the roles that take place in the product packaging by length, width, and height.

- Product Protection

- Cost Efficiency

- Storage Optimization

Product Protection

When the box is accurately sized, it means there is no space, which can protect the object during shifting or handling. It will ensure the reduction of damage risk, and the project will arrive at the customer’s doorstep in its original shape without any damage. This can help to improve the unboxing experience of the customer.

Cost Efficiency

Another role played by the dimensions is cost-efficiency in shipping. Some of the carriers use the dimension technique to charge according to the minimal packaging size, not according to its original size. With the right dimensions, the box will exist in its original size. It cannot be oversized and saves the extra cost of shipping in the van.

Storage Optimization

The right dimensions of internal and external can speak about the available space in the warehouse, and whether the delivery van is enough or not. Dimension can allow optimizing the storage before placing the order.

What Are Length, Width, And Height?

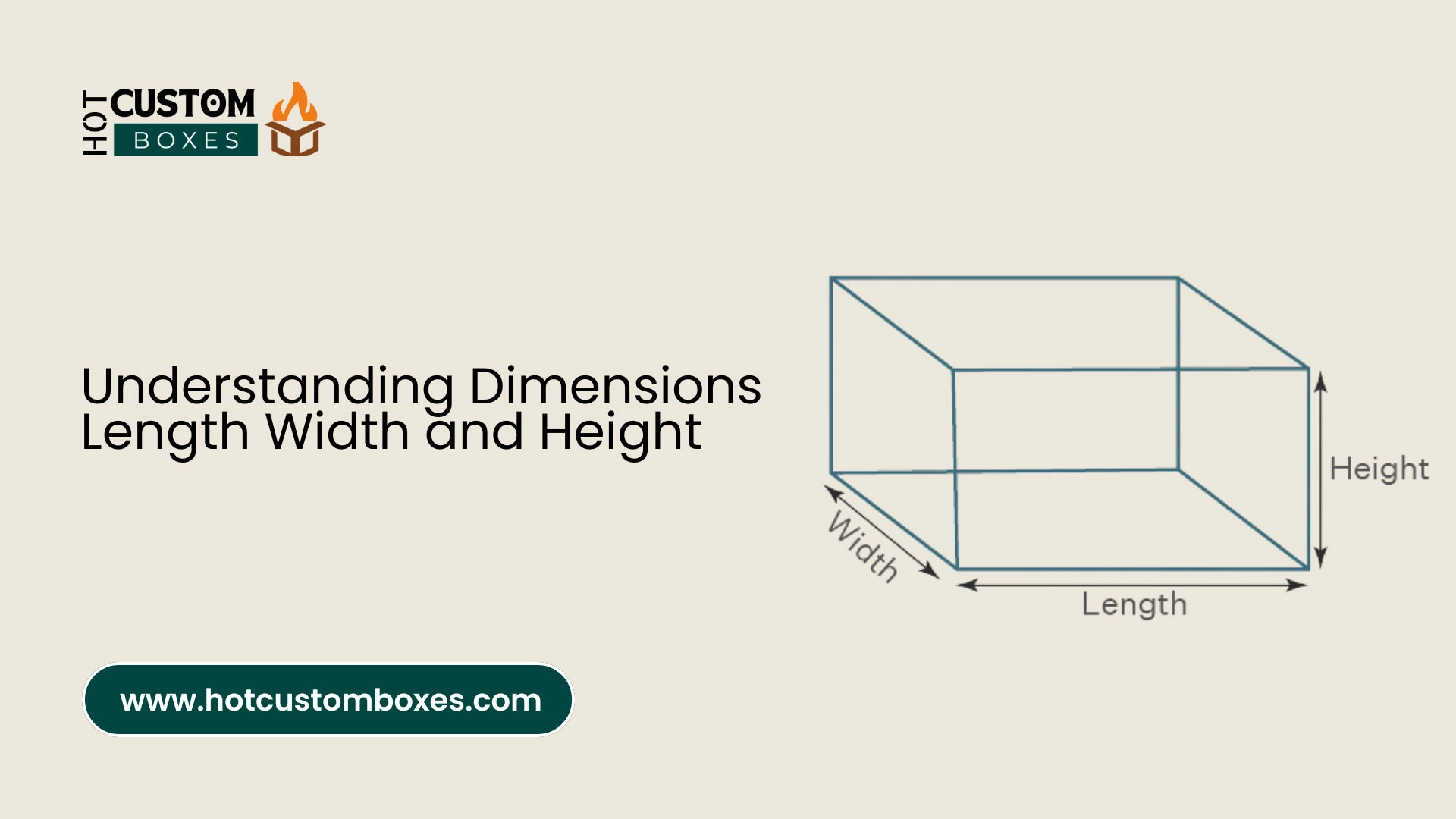

Length, width, and height can calculate the accurate size of the product or object. This can be commonly used to measure the dimensions of the boxes. This is a very important part to measure the custom size and shape to reduce the cost, optimize the space, and protect the product. Before measuring the dimension, check out the following: length, width, and height.

A Step-By-Step Guide To Measuring The Volume Of A Box

To calculate the right volume of a box, you have to mind height, length, and width. These can help in various things, such as with the accurate size, and the delivery will be hassle-free. To measure the volume of a box, the formula commonly used is

Volume = Length x Width x Height

For example, a standard shipping box has 16” length, 12” width, and 12’ in depth/height. The above formula will be applied accordingly (Volume = 16 x 12 x 12). You will know that a standard shipping box’s volume will be 2,304 cubic inches

Understanding 2D and 3D Dimensions?

- Two-Dimensional (2D) Boxes

- Three-Dimensional (3D) Boxes

Two-Dimensional (2D) Boxes

A two-dimensional (2D) box is a flat shape with only two dimensions: length and width. It has no depth or height, so it does not have volume.

2D packaging is mainly used for flat items that do not need extra space. Common examples include packaging for photographs, canvas prints, certificates, and legal documents.

Three-Dimensional (3D) Boxes

A three-dimensional (3D) box is a solid object with three dimensions: length, width, and depth (or height). Because it has depth, a 3D box has volume and can hold physical items inside it. These 3-dimensional boxes can be ideal to ship items like soap boxes, gable boxes, and pillow boxes. This can be used in everyday life.

The Correct Order Of Length, Width, And Height

The standard order to measure a box’s dimensions is Length x Width x Height. However, the length, width, and height measurement order sometimes depends on whether the box is horizontal or vertical.

- Height Width Length Order

- Height Length Width Order

- Length Height Width Order

Height Width Length Order

The height, width, and length dimensions can vary depending on what type of product packaging you want to measure. Every brand has a different size guide and follows the measuring techniques accordingly. They measure height first, followed by width and Length. This order is often used for vertical boxes.

Height, Length, Width Order

The height, length, and width order is followed for the object or box in a horizontal shape. First, you have to measure height, and then length, and then, in the last, width can be calculated. The order could be different, but the formula will apply in the same way to calculate the cubic size and dimensional weight.

Length Height Width Order

If you see the box from the side view, you will follow the Length, Height, Width order. Look at the box from its front panel and turn it to 90 degrees. Now start measuring the length, which is usually smaller than the height and width.

Length Vs Width

If we talk about cubes and rectangular prisms, length and width are at right angles to each other. From the front, both these dimensions combine to give a two-dimensional image to objects. The length and width of product boxes decide how long and wide products can be packed inside the packaging boxes.

Width Vs Height

Width and height are also at right angles to each other. However, the front view hides the height of a cuboid or rectangular prism box. These dimensions combine to decide the depth and width of items that can be accommodated in the packaging boxes.

Height Vs Length

Like width vs height, length also shadows the height of a cube from the front view. Dimensions of products from left to right and front to back are determined by the height and length of the packaging boxes.

Length, Width, And Height Key Differences

| Aspect | Length | Width (Breadth) | Height (Depth) |

| Definition | Longest horizontal dimension | Shorter horizontal dimension | Vertical dimension |

| Direction | Horizontal, longest side | Horizontal, shorter side | Vertical (upward or downward) |

| Orientation | Along the object’s maximum extent | Perpendicular to length | Perpendicular to both length and width |

| Common Units | m, cm, in, ft | m, cm, in, ft | m, cm, in, ft |

| Example Object | Length of a table (e.g., 2 m) | Width of a table (e.g., 1 m) | Height of a table (e.g., 0.8 m) |

| Applications | Measuring distance, furniture, and roads | Measuring screens, books, and doorways | Measuring buildings, shelves, and water depth |

Measuring The Internal Dimensions Of A Box

When you have done the three dimensions of your box, then there is a very important factor left that is the internal dimension. You have to always keep the internal dimension as well. This can make the box more crucial because in the packaging industry, both dimensions can matter internally or externally as well.

With the help of these internal dimensions, boxes can act as a protective case. This can increase the unboxing experience and make the packaging more effective for both the user and manufacturer. Internal dimensions can matter precisely for the custom-sized boxes.

Accurate Box Measurements: Tips For Measuring Length, Width, And Height

Before measuring the dimensions of a box. You have to check that nothing will be missed, such as a measuring tape, a small ruler, and a notepad to write the dimensions. Firstly, you have to calculate the tallest side of the box from top to bottom accurately for the height. Then you have to move along the side of length, and then in the last width. Use a small ruler to measure small mailer boxes and a large yardstick for large boxes.

- Identify The Dimensions

- Internal Vs. External

- Standardize Order

- Use Correct Tools

- Double-Check

Identify The Dimensions

When you place the box in the upright position, then the opening side of the box will be the length, and the shorter side of the box is the width, or the top to bottom is the height of the box.

Internal Vs. External

Measure inside for product fit and outside for shipping costs. Note that exterior dimensions will be slightly larger due to cardboard thickness.

Standardize Order

Always write down the dimensions according to the formula Length x Width x Height.

Use Correct Tools

Measuring from edge-to-edge. Use a rigid tape measure for accurate measurement.

Double-Check

Re-measure all sides to avoid cumulative errors. Include Packing Material: If calculating shipping size, account for bulging or padding.

Common Tools Used To Measure Length, Width, And Height

To fit the product in the box then it is very important to measure the boxes accurately with the perfect tools. It can help to take the exact length, width, and height. The following are the tools that can be used to measure the dimensions of the boxes.

- A caliper to measure thickness.

- Rulers to measure length, width, and height separately.

- Flexible measuring tapes to measure the perimeter of the boxes

How To Record Box Dimensions Correctly (Length, Width, And Height)?

When measuring a box, following the correct order is important to ensure precision. Wondering what the correct order of a box’s dimensions is? The following is the correct order you should follow:

Length x Width x Height

- Length – the widest length of the box from left to right

- Width – the shorter side form the box’s front view.

- Height – the measurement from the box’s top to bottom.

Final Thoughts

We have discovered that accurate measurements are crucial to offer a snug fit to any product throughout shipping. Hot Custom Boxes is here to help you understand concepts of length, width, and height. We know that this empowers you to better navigate and interact with the physical product for the future.

From selecting the right size of product, these fundamental dimensions are used everywhere. Whether you are new to the packaging industry or just curious about the objects around you, this must be the place to understand.

Hope you have learned about the length and depth in our guide and will make proper decisions for the next time. If you need any assistance, boxes, or other packaging services, just count on us. We are always at your service.

Frequently Asked Questions (FAQs)

First, measure length and width. After these two measurements of length have been taken, height, going perpendicular to the other two sides, can be obtained.

- Length: The longest side of an object or box. It usually refers to the measurement from one end to the other along the horizontal plane.

- Width: The measurement of the side perpendicular to the length. It is usually the shorter side of the base of the object or box.

The correct formula is Length x Width x Height. Use this for your measurements.

All of the dimensions of a box are:

- Length (L): The longest side of the box, usually measured along the base.

- Width (W): The shorter side of the base, perpendicular to the length.

- Height (H): The vertical measurement from the bottom to the top of the box.

First, measure length and width. After these two measurements of length have been taken, height, going perpendicular to the other two sides, can be obtained.

To describe the dimensions of an object, you provide its Length, Width, and Height (L × W × H):

- Length: The longest side of the object.

- Width: The shorter side, perpendicular to the length.

- Height: The vertical measurement from the base to the top.

“10 × 12” refers to a dimension of 10 feet by 12 feet, totaling 120 square feet of area.

- 10 = Length (the longer side, usually in inches, cm, or your chosen unit)

- 12 = Width (the shorter side, perpendicular to the length)