How Material Choice Affects Packaging Durability

Home » How Material Choice Affects Packaging Durability

Table of Contents

Get A Free Quote

Material choice affects packaging durability in many ways across various industries. Packaging of a product is considered a first physical interaction between the brand and the consumer. If the packaging is not attractive and durable, then customers will probably not get along with that product and brand. Imagine if a package during handling or transportation is damaged or leaked and delivered to the customer, then it will create a negative unboxing experience, and this will harm your brand image as well.

So if you choose durable and eco-friendly materials for your product packaging with a deep understanding of the psychology of packaging design and the latest packaging trends, then your brand will outshine the whole market. It will help in building customers’ trust in your brand and influence purchasing decisions. Proper packaging ensures that your products arrive safely at their destination without damage while maintaining quality and improving customer unboxing experience.

In this article, we will explore why durability matters and what factors to consider that influence packaging, with examples of different industries. Let’s dive in!

Why Durability Is Important In Packaging?

Durability in packaging matters as it protects the products from damage, reduces refunds and enhances consumer’s experience. Here are some of the factors why durability is important:

- Protection: It provides protection to the products during shipping and handling.

- Cost-Effective: It helps to reduce costs as refunds and replacements of damaged products become lower.

- Sustainability: By using eco-friendly materials, packaging can be reused and recycled, which helps to lessen the environmental impact.

- Build Customer Trust: It helps in building customer trust in your brand through a satisfied unboxing experience and boosts brand image.

Factors That Influence Packaging Durability

Apart from material selection, there are many other factors that influence packaging durability which are shown in the table below:

| Factors | Description |

|---|---|

| Thickness and Density | Thicker and denser materials like rigid and corrugated provide extra protection and withstand pressure. |

| Environmental Conditions | Environmental conditions such as water, heat and humidity can also affect packaging that’s why temperature resistant material should be used. |

| Handling & Transit | Rough handling and other shipping rigors also affect packaging. That’s why sturdy and robust material should be used for this purpose. |

| Protective Coatings | Protective coatings like waterproof, UV coatings can be added to packaging boxes for scratch proof shipping and transit. |

| Product Weight | Weight of the products also matter as heavy items require paperboard and cardboard material options for custom boxes and lighter goods can rely on kraft or packaging films. |

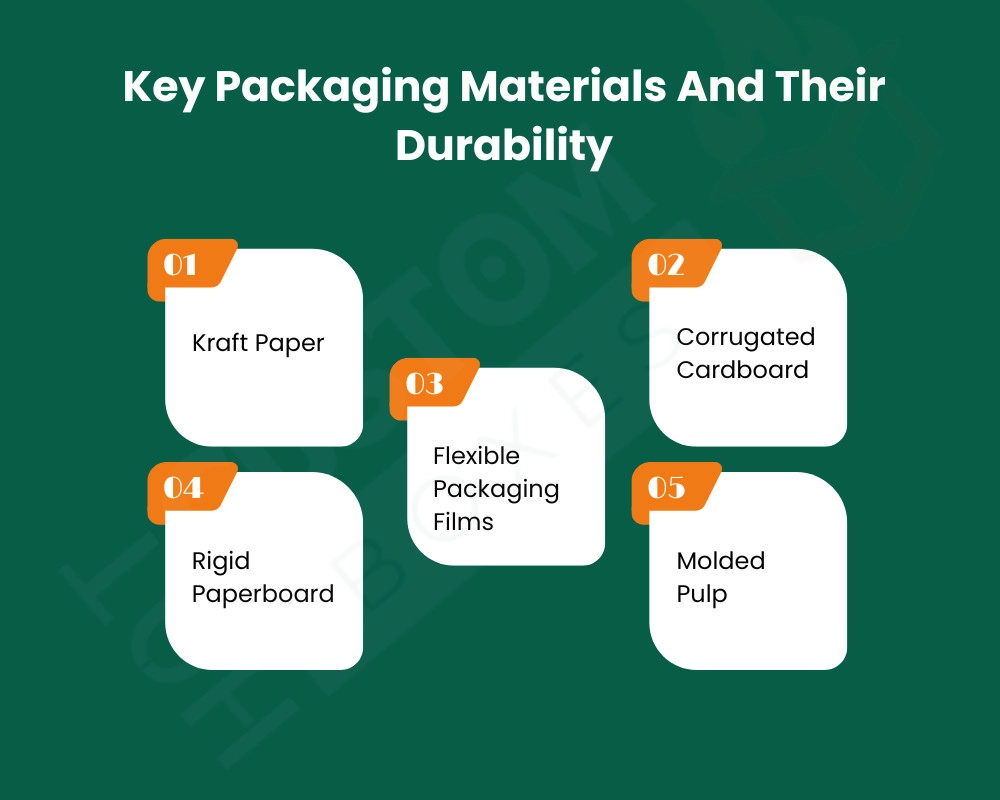

Key Packaging Materials And Their Durability

Here are some of the best packaging materials and their durability for different packaging solutions:

- Kraft Paper

- Corrugated Cardboard

- Flexible Packaging Films

- Rigid Paperboard

- Molded Pulp

Kraft Paper

Kraft paper is made from wood pulp. It is an eco-friendly, recyclable material and is durable for packaging items that are lightweight. Businesses looking for eco-friendly materials should invest in custom packaging. Kraft paper packaging material is widely used in making paper bags, wrapping sheets and custom boxes. Here are some of the durability factors of kraft paper:

- It provides strength to the packaging and is tear-resistant.

- Kraft paper can be used inside the packaging for extra protection.

- It is heat and moisture-resistant and keeps the product safe from environmental factors.

Ideal For:

Kraft Paper is ideal for retail packaging, food wraps and for eco-conscious brands.

Corrugated Cardboard

Corrugated cardboard is used widely in various industries due to its strength and durability. It consists of different layers and flutes that make it an ideal choice for heavy-duty shipping and transit. You can also customize corrugated cardboard thicknesses, which are as follows:

| Flutes | Description |

|---|---|

| A-Flute | 5mm thick, suitable for heavy-duty shipping and fragile items. |

| B-Flute | 3mm thick, a versatile all-rounder used in many types of packaging. |

| C-Flute | 4mm thick, commonly used for general-purpose packaging. |

| E-Flute | 1.5mm thick, ideal for retail packaging and small mailers. |

| F-Flute | 1mm thick, used for very small retail packaging. |

These thicknesses can help in protecting the product from damage. Here are some of the durability components of corrugated cardboard:

- Corrugated cardboard is lightweight and can help in reducing shipping costs.

- It provides extra strength and cushioning to the products.

- It is recyclable and can protect fragile to heavy-weight products.

Ideal For:

Corrugated cardboard is ideal for e-commerce packaging, shipping boxes, subscription packaging and electronics applications.

Flexible Packaging Films

Flexible packaging films are now becoming popular in different industries due to their eco-friendliness, versatility and durability. They protect the product and keep the items fresh for a longer time. They are made from different materials like aluminium foil and paper. Here are some of the durability factors of flexible packaging films:

- They provide resistance to light, heat and moisture that help to keep items fresh.

- They are compostable and can be recycled, which helps to reduce the carbon footprint.

- Packaging films can improve the shelf life of perishable items.

Ideal For:

Flexible packaging films are ideal for snacks, frozen foods and single-use items.

Rigid Paperboard

Rigid paperboard is made from compressed layers of thick paper. They are durable and protect the products due to their sturdy structure. It maintains its shape even in rough handling or shipping. It is the best choice for businesses looking for durable packaging with a luxury touch for their premium products. It also enhances customers’ experience and can be reusable. Here are some of the durability factors of rigid paperboard:

- It provides structural integrity and is best for shipping high-end or delicate products.

- It offers high tear-resistant and water-resistant properties.

- Unlike corrugated boxes, rigid supports high-end finishes that also add a protective layer to the boxes.

Ideal For:

Rigid paperboard is ideal for gift packaging, jewellery packaging, cosmetics packaging and electronics.

Molded Pulp

Molded pulp is made from recycled paper, cardboard or renewable fibers to protect products. These are widely used nowadays in luxury packaging for a premium unboxing experience. They are popular due to their shock-absorbing feature that helps to protect the product. Here are some of the durability factors of molded pulp:

- They are used for protecting the delicate items from damage during shipping and handling.

- They help maintain structural integrity in a larger package.

- They are recyclable and keep the environment safe.

Ideal For:

Molded pulp is ideal for gift packaging, luxury product packaging and electronics.

Industry Examples Of Materials' Impacts On Packaging Durability

Here are some of the real world examples of material choices that impact packaging durability:

- E-commerce Industry

- Retail Industry

- Food Industry

- Electronics Industry

E-commerce Industry

Ecommerce businesses use corrugated cardboard with bubble wraps and extra cushioning to protect their products during shipping and handling.

Retail Industry

Luxury retail uses luxury packaging materials like rigid paperboard for packaging. It is used in packaging items like watches, gifts, perfumes, jewellery and cosmetics.

Food Industry

The food industry uses different packaging for different food items. They use flexible packaging films for snacks and other perishable goods. For cereal boxes, kraft paper can be used for packaging.

Electronics Industry

The electronics companies use extra protection for its electronic items to prevent damage. For this purpose, they use a combination of corrugated cardboard with molded pulp to protect laptops, LEDs, etc. from damage.

Durability Vs Sustainability

Durability means the ability of an object to last for a long time, whereas sustainability is the ability to meet needs without compromising future generations. Both of these are connected to each other as durable packaging made from eco-friendly materials can have less environmental impact than the packaging made from plastics and other unsustainable materials.

While manufacturing durable packaging for your products, you should keep sustainability in your mind. Selecting the right biodegradable materials is best for sustainable and durable product packaging. At Hot Custom Boxes, we balance product protection with resource efficiency. We design sustainable packaging with eco-friendly materials that consider the full lifecycle of products and materials.

Comparison Between Packaging Materials For Durability

| Materials | Strength | Barrier Protection | Eco-friendly | Best Uses |

|---|---|---|---|---|

| Kraft Paper | Moderate | Low | Excellent | Heavy items, wrapping and eco-friendly packaging. |

| Corrugated Cardboard | High | Moderate | Excellent | Shipping and transit. |

| Flexible Packaging Films | Moderate | Very High | Moderate – High | Food packaging, products that need moisture protection. |

| Rigid Paperboard | Very High | Moderate | Good | Luxury packaging, products that required protection. |

| Molded Pulp | High | Moderate | Excellent | Protects fragile items like jewellery, cosmetics, electronics etc., during transit. |

Connect With Hot Custom Boxes And Choose The Right Packaging Material

Fill out the free quote form or call us at (332) 263-6086 and our experts at Hot Custom Boxes will guide you to choose the best packaging material for your products. Follow us on Facebook, LinkedIn or Pinterest for more information!